Crosskarts are high-performance, off-road racing vehicles that require strong and durable bodywork to protect the driver and other vital components of the car. The bodywork of crosskarts can be made from different materials, including fiberglass, plastic, and aluminum, each with its own unique features and benefits.

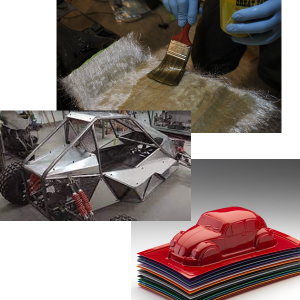

Fiberglass is a composite material made by combining glass fibers with a resin. To create a fiberglass bodywork for a crosskart, a mold of the desired shape is made from foam, wood, or plastic. The mold is then covered with layers of fiberglass cloth and saturated with resin. After curing, the excess fiberglass is trimmed away, and the bodywork is finished to the desired specification. Fiberglass bodywork is lightweight, strong, and customizable.

Plastic panels, made from HDPE or polycarbonate, are heated and pressed into a mold, then trimmed to the desired shape. They are a cost-effective option for mass production and are resistant to impacts and abrasion, ideal for off-road racing.

Aluminum panels are cut and shaped into the desired size and shape, then welded together to create the final bodywork. They are durable, resistant to impacts and abrasion, and easy to repair.

In conclusion, choosing the right bodywork material for your crosskart depends on your needs and budget. Fiberglass, plastic, and aluminum are all viable options, each with its pros and cons. Fiberglass is lightweight and easy to customize, plastic is cost-effective and resistant to impacts, and aluminum is durable and easy to repair. By considering the characteristics of each material, you can select the best one for your racing needs.

Fiberglass is a composite material made by combining glass fibers with a resin. To create a fiberglass bodywork for a crosskart, a mold of the desired shape is made from foam, wood, or plastic. The mold is then covered with layers of fiberglass cloth and saturated with resin. After curing, the excess fiberglass is trimmed away, and the bodywork is finished to the desired specification. Fiberglass bodywork is lightweight, strong, and customizable.

Plastic panels, made from HDPE or polycarbonate, are heated and pressed into a mold, then trimmed to the desired shape. They are a cost-effective option for mass production and are resistant to impacts and abrasion, ideal for off-road racing.

Aluminum panels are cut and shaped into the desired size and shape, then welded together to create the final bodywork. They are durable, resistant to impacts and abrasion, and easy to repair.

In conclusion, choosing the right bodywork material for your crosskart depends on your needs and budget. Fiberglass, plastic, and aluminum are all viable options, each with its pros and cons. Fiberglass is lightweight and easy to customize, plastic is cost-effective and resistant to impacts, and aluminum is durable and easy to repair. By considering the characteristics of each material, you can select the best one for your racing needs.